Table of Contents

- Introduction

- Understanding Pump Types

- Assessing Fluid Properties

- Evaluating Flow Rate and Pressure Requirements

- Material Selection and Durability

- Energy Efficiency and Operating Costs

- Installation and Maintenance Considerations

- Compliance with Regulatory Standards

- Common Mistakes to Avoid

Selecting the right industrial pump is a decision that can significantly impact the efficiency, reliability, and cost-effectiveness of your facility’s operations. Whether you are working in manufacturing, wastewater treatment, or chemical processing, the initial step toward achieving operational excellence is understanding the variables that influence pump selection. With the broad range of pump types, materials, and configurations available, successfully navigating this landscape is key to preventing costly errors and downtime. If you’re looking for professional assistance in selecting, installing, or maintaining industrial pumps, C&B Equipment provides comprehensive solutions tailored to your needs.

Choosing the right pump involves considering operational demands, fluid properties, system requirements, and long-term costs. Neglecting these factors can lead to breakdowns and high repair costs. Proper pump selection ensures efficiency, reduces energy costs, and enhances system longevity. Improper choices can lead to inefficiencies and hazardous conditions. Collaborating with experts and utilizing high-quality components helps overcome potential issues, supporting optimal performance and equipment maintenance.

Understanding Pump Types

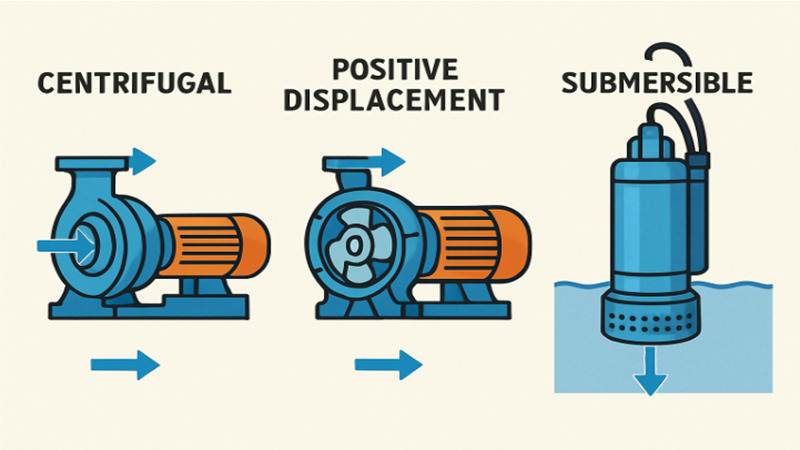

The variety of industrial pump technologies available means there’s a solution suited for almost any task—if you know what to look for. The most common pump types include:

- Centrifugal Pumps: These are best for high-flow, low-viscosity fluids such as water or light oils. Their efficiency and simple design make them a top choice for many general applications.

- Positive Displacement Pumps:Preferred for moving high-viscosity fluids or providing precise flow rates, these pumps excel in metering and dosing tasks as well as handling slurries and thicker materials.

- Submersible Pumps: Designed to operate entirely underwater, these units are ideal for dewatering, drainage, and sump applications.

- Specialty Pumps: These include magnetic drive pumps, sanitary pumps for the food and pharmaceutical industries, and chemical process pumps designed for highly specialized environments.

Selecting the right pump type narrows down your options while providing a logical starting point for further specification.

Assessing Fluid Properties

The pump must be compatible with the characteristics of what it’s moving. Consider the following:

- Viscosity: Heavier, thicker fluids usually require positive displacement pumps to maintain steady flow and avoid excessive wear.

- Corrosiveness: Aggressive chemicals or brine solutions demand pumps constructed of materials resistant to corrosion and chemical attack.

- Temperature: Fluids at elevated or subzero temperatures impact pump performance and component longevity, sometimes warranting specialty seals or materials.

- Presence of Solids: Slurries and fluids containing abrasive particles may require pumps designed with larger clearances and more robust internal passages.

Careful analysis of fluid properties avoids mismatches that could shorten pump life or yield subpar performance.

Evaluating Flow Rate and Pressure Requirements

Failure to accurately size pumps to match the flow and pressure requirements of your process leads to inefficiency, excess energy consumption, and increased maintenance. Begin by calculating the desired volume over a set time (flow rate) and the resistance or head the pump must overcome (pressure). Selecting a pump that operates near its best efficiency point ensures smoother operation and can substantially reduce energy costs.

Material Selection and Durability

The long-term viability of your pump depends on selecting durable, chemically compatible materials:

- Cast Iron: Reliable for general applications with non-corrosive fluids, offering good strength at an economical price.

- Stainless Steel: Used in environments where corrosion resistance is essential, including food, beverage, and chemical processing.

- Specialized Alloys: Required for environments involving severe corrosion, abrasion, or demanding temperature extremes.

The initial investment in high-quality materials pays dividends by minimizing unplanned downtime and extending pump lifespan.

Energy Efficiency and Operating Costs

Pumps can account for a significant portion of your facility’s energy use, making efficiency a top priority. Select pumps equipped with high-efficiency motors, and consider using Variable Frequency Drives (VFDs) to adjust performance on the fly and match process demands. Proper sizing is critical, as over-sizing leads to energy waste, while under-sizing can lead to system failure. Reducing energy consumption also supports sustainability targets, benefiting the environment and the bottom line.

Installation and Maintenance Considerations

Planning for accessibility and ease of maintenance is vital during pump selection. Look for models that allow for regular inspection without requiring the disassembly of significant components. Prioritize pump brands and models with dependable spare parts availability and responsive manufacturer support. A system designed for maintainability encourages proactive care, minimizing costly, unexpected shutdowns and simplifying repairs when needed.

Compliance with Regulatory Standards

Any industrial pump installation must adhere to applicable industry and governmental regulations. Compliance ensures a safer workplace and shields your organization from legal or financial penalties. Familiarize yourself with relevant local, national, and industry-specific standards, such as environmental, safety, and food-grade regulations, which may influence pump choice and design.

Common Mistakes to Avoid

- Overlooking Fluid Properties:Selecting incompatible materials or pump designs results in premature damage and failure.

- Incorrect Sizing: Pumps that are too large or too small for their intended duties reduce efficiency and escalate maintenance issues.

- Ignoring Maintenance Needs: Failing to account for maintenance access or parts availability leads to unnecessary downtime.

- Focusing solely on Initial Cost: Judging purely on purchase price neglects the ongoing energy and maintenance expenses, which often cost more in the long run.

Taking a holistic approach at every step of pump selection prevents future headaches and major operational setbacks. In summary, selecting an industrial pump depends on carefully considering your system’s unique operational characteristics. By evaluating pump type, material, energy usage, fluid properties, and maintenance needs, facility managers and engineers can achieve reliable, efficient, and regulatory-compliant pumping solutions that drive long-term success.